特性/ Features

Tg:135±5℃ (DSC)

UV Blocking与 AOI兼容可提高PCB生产效率

UV Blocking and AOI compatible,so as to increase productivity efficiency

可依需求提供不具UV阻挡功能的自然色板材(白料)

No UV Blocking and natural color CCL upon request

可依需求提供介电常数为:4.3±0.3(1MHz)的FR-4板材

According to necessity to provide a dielectric constant 4.3±0.3(1MHz) of FR-4 plate

应用领域/ Applications

适合于2-6层PCB、计算机及外围设备、通讯设备、办公自动设备等。

Suitable for medium multilayer printed circuit board, computer, communication equipment, OA equipment, etc.

不建议使用于有CAF需求的应用。

Not suggested for application with CAF requirement.

不建议使用于>2OZ铜厚and HDI。

Not suggested for>2OZ copper and HDI.

主要特性 / General properties

检测项目 Item | 单位 Unit | 检测条件 Test Condition | 测试方法 IPC-TM-650 | 典型值 Typical Value | |

玻璃化转变温度Tg | ℃ | DSC | 2.4.25 | 134.3 | |

剥离强度 1oz Peel Strength | N/mm | 288℃, 10S | 2.4.8 | 1.81 | |

热应力 Thermal stress | S | 288℃,solder dip | 2.4.13.1 | 120 s No delamination | |

弯曲强度 Flexural Strength | N/mm2 | LW/CW | 2.4.4 | 580/485 | |

燃烧性 Flammability | Rating | E 24/125 | UL94 | V-0 | |

表面电阻 Surface Resistivity | MΩ | After moisture | 2.5.17.1 | 5.16×107 | |

体积电阻 Volume Resistivity | MΩ·cm | After moisture | 2.5.17.1 | 5.07×108 | |

介电常数 Dielectric Constant | - | C 24/23/50 | 2.5.5.9 | 4.8 | |

介质损耗角正切 Loss Tangent | - | C 24/23/50 | 2.5.5.9 | 0.015 | |

耐电弧 Arc Resistance | S | D48/50+D0.5/23 | 2.5.1 | 125 | |

击穿电压 Dielectric Breakdown | KV | D48/50+D0.5/23 | 2.5.6 | 58 | |

吸水率 Moisture Absorption | % | D24/23 | 2.6.2.1 | 0.15 | |

热分解温度Td | ℃ | Weight Loss 5% | 2.2.24.6 | 310 | |

CTE Z-axis | Alpha 1 | ppm / ℃ | TMA | 2.4.24 | 60 |

Alpha 2 | ppm / ℃ | 2.4.24 | 300 | ||

50 - 260 ℃ | % | 2.4.24 | 4.3 | ||

相比漏电起痕指数 CTI | Rating | C-96/20/65 | IEC-60112 | PLC 3 | |

Specimen Thickness : 1.6mm ; Specification sheet:IPC-4101D/21,is for your reference only

半固化片介绍-H140AP/ Prepreg instruction

H140A P (UV Prepreg):

prepreg type | Resin Content(%) | 压合厚度Cured thickness(mm/mil) | ||||

含量R/C(%) | 公差Tolerance | Nominal | Range(±)mil | |||

% | ± | mm | mil | mm | mil | |

7628HRC | 52 | 2 | 0.247 | 9.72 | 0.025 | 1.00 |

50 | 2 | 0.234 | 9.21 | 0.023 | 0.90 | |

48 | 2 | 0.224 | 8.82 | 0.023 | 0.90 | |

7628 | 45 | 2 | 0.207 | 8.15 | 0.021 | 0.80 |

43 | 2 | 0.197 | 7.76 | 0.02 | 0.80 | |

1506 | 50 | 2 | 0.184 | 7.24 | 0.018 | 0.70 |

48 | 2 | 0.173 | 6.81 | 0.017 | 0.70 | |

45 | 2 | 0.163 | 6.42 | 0.016 | 0.60 | |

2116 | 60 | 2 | 0.155 | 6.10 | 0.015 | 0.60 |

58 | 2 | 0.147 | 5.79 | 0.015 | 0.60 | |

55 | 2 | 0.135 | 5.31 | 0.014 | 0.50 | |

53 | 2 | 0.127 | 5.00 | 0.013 | 0.50 | |

50 | 2 | 0.119 | 4.69 | 0.012 | 0.50 | |

1080 | 68 | 2 | 0.094 | 3.70 | 0.009 | 0.40 |

66 | 2 | 0.088 | 3.46 | 0.008 | 0.30 | |

63 | 2 | 0.079 | 3.11 | 0.008 | 0.30 | |

61 | 2 | 0.074 | 2.91 | 0.008 | 0.30 | |

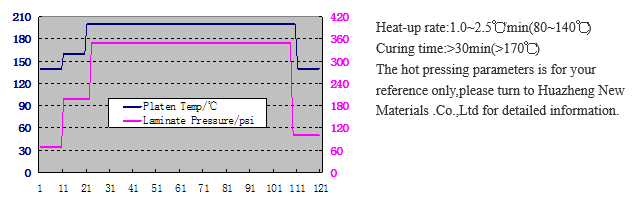

建议压制程式: Suggest cycle

储存条件:温度≤23℃、湿度≤50%,保存时间3个月;温度≤5℃、密封条件下,保存时间6个月.

Storage Condition: T≤23℃& ≤50%RH,Within 3 months; T≤5 ℃ Within 6 months (seal condition).

在上述要求内,我司可立即安排PP送样;若有特殊要求,由供需双方商定。Follow above condition,

Our company will arrange sample immediately. We can disscuss if you have special requirement.